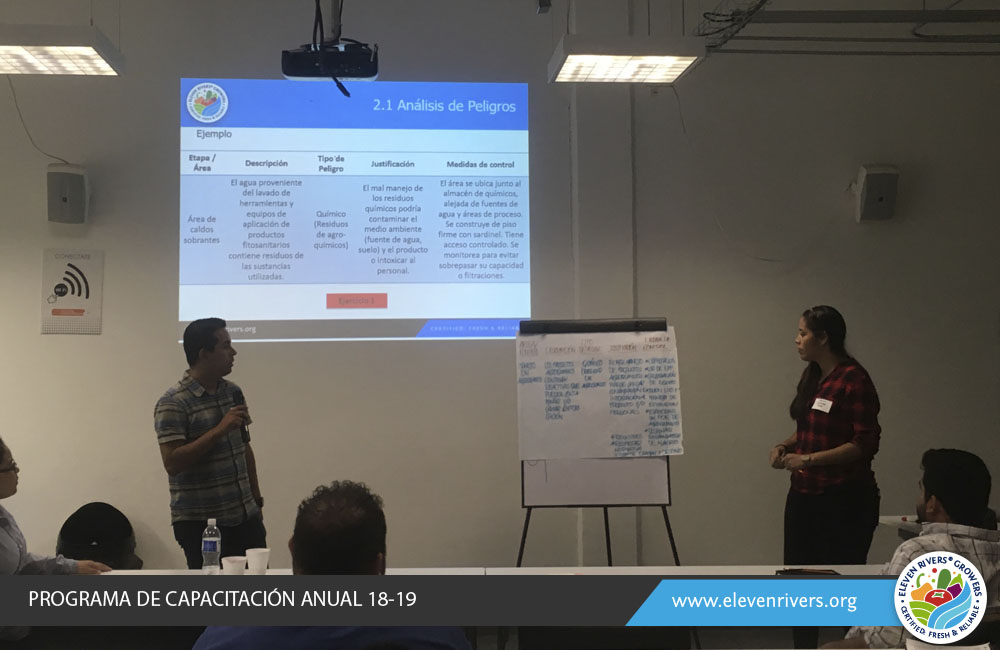

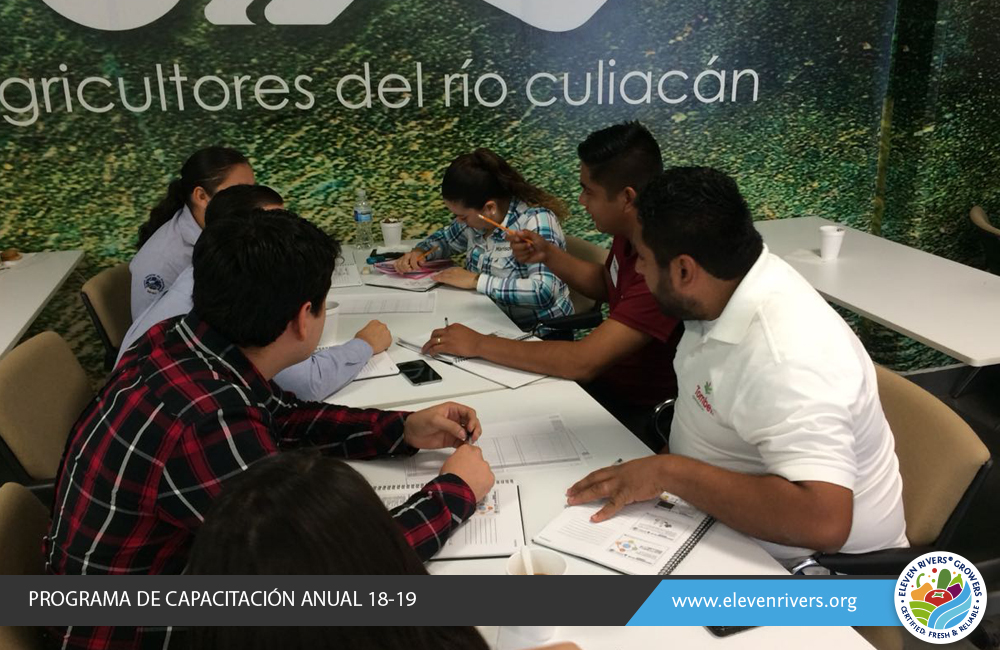

It begins the annual Eleven Rivers Training Program

On June 06th, our annual training program began, this time the program was divided into two phases:

Basic training: It has the purpose that each person is able to understand and apply a quality system of processes, safety in the field and packaging, HACCP and social responsibility and that these at the same time generate the conditions of their environment labor as a personal replicator knowledge.

Advanced training: Its main objective is to deepen the knowledge of the components established in the basic work.

Our training program seeks to improve the processes of the grower companies of Sinaloa, through the formation of the employees of the companies.

We are grateful for the Confederation of Agricultural Associations of Sinaloa (CAADES) The Grower Association of the Culiacan River (AARC) both organizations that hosted the 10 courses that have been taught in the city of Culiacán.

Our program was attended by 40 technicians per course, who are collaborators of the agricultural companies of Sinaloa participating in the Eleven Rivers Program.

The courses carried out were:

June 06 and 07, 2018 | Implementation of axis I. Process Quality System

Speaker: Biol. Chrysthian Marisol Castro Sandoval Objectives: In this course the technician will learn the basic tools to implement a quality management system in the agricultural industry. The technician can maintain the quality in the documentation of the company, have clear and complete information of the processes, identify the nonconformities to face it and the challenges derived from a crime of contamination.

June 08, 2018 | Implementation of axis II. Agricultural Production System

Speaker: IBQ. Edgar Saúl Ramírez Guerrero Objectives: In this course, the results of the questions that refer to the products that are marketed in the field area, the availability of risk analysis in the industry, the adherence to the national and international regulations, know the elements of good agricultural practices that seek to reduce horticultural products that are contaminated by physical, chemical or biological agents.

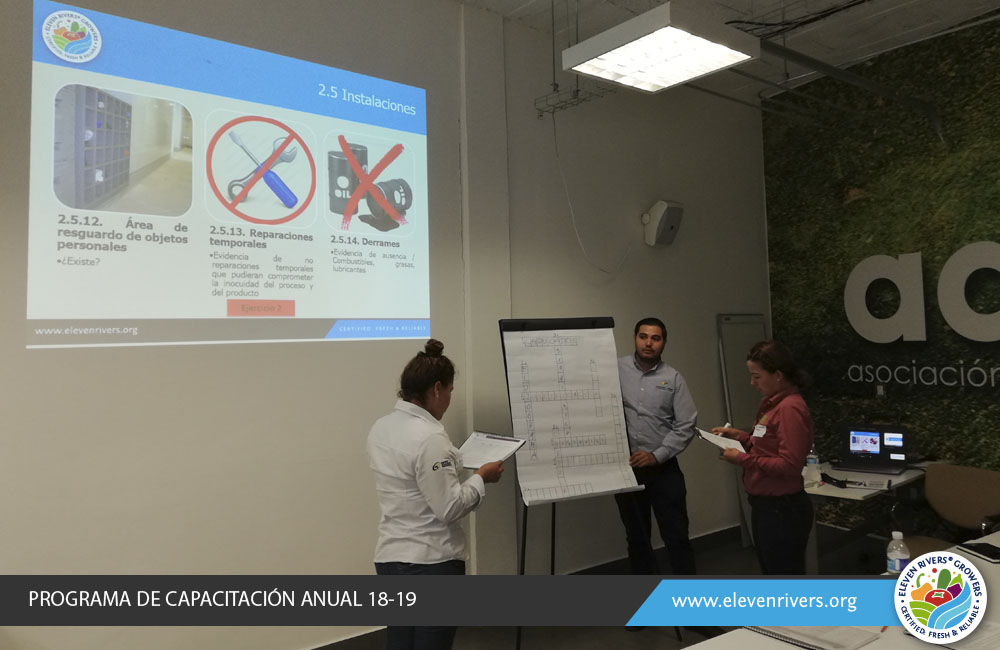

June 13 and 14, 2018 | Implementation of axis III. Packaging, Storage and Transportation System

Speaker: IBQ. César López Valdez Objectives: Identify the situations that could generate contamination in the products commercialized by the company specifically in the packaging area, based on risk analysis that helps us to implement good manufacturing practices applicable to the sector, in accordance with national and international regulations. know the processes in which value is added to reach the final market, under the criterion of quality, with the objective of integrating the safety factor into those processes.

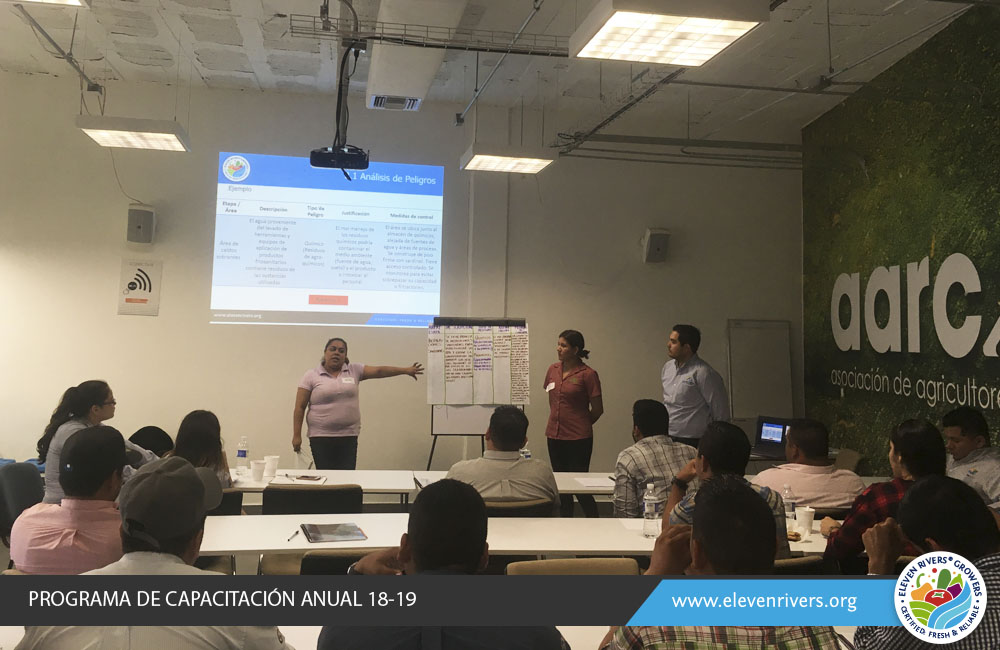

June 15, 2018 | Implementation of the IV axis. Eleven Rivers system based on HACCP.

Speaker: QFB. Elvia Rosa Martínez Bueno Objectives: The preliminary steps and the basic principles to implement the HACCP methodology based on the codex alimentarius, to know and apply the tools based on the hazard analysis and critical control points described in that axis.

June 22, 2018 | Integrated Water Management

Speaker: Ing. Francisco de Asís Morales Objectives: To know the national regulations for the safe final destination of the wastewater coming from the agricultural operation, including the one generated in the shelters. NOM-001-SEMARNAT-1996 / discharge in national assets and NOM-002-SEMARNAT-1996 / unloading in public sewage system.

June 26 and 27, 2018 | Development and Implementation of Risk Analysis

Speaker: Ing. Josué Figueroa Objectives: To know the national regulations for the safe final destination of the wastewater coming from the agricultural operation, including the one generated in the shelters. NOM-001-SEMARNAT-1996 / discharge in national assets and NOM-002-SEMARNAT-1996 / unloading in public sewage system.

June 28 and 29, 2018 | Corrective actions

Speaker: Ing. Josué Figueroa Objectives: To know the most common mechanisms to follow for the execution of corrective actions, the conditions in which they must be applied, as well as their implementation and follow-up in order to avoid recurring deviations. Develop a procedure and record to solve problems in case of deviation from compliance criteria.